About concrete

A First European Solidia industrial pilot installation at a UK precaster site

In June 2016, the European LIFE program provided the award grant N° LIFE15 CCM/FR/000116 to the Solid LIFE project. This grant funds LafargeHolcim, Solidia Technologies® and Building Research Establishment efforts to develop and deploy this technology within Europe. In the framework of Solid LIFE project, several precast applications of Solidia Technology were foreseen within Europe. After two small scale pilot testings in partnership with Solidia Technologies®, a UK precaster decided to move on to an industrial pilot scale with the technology.

Solidia Curing Chamber (right), Gas Conditioning System (left)

Beginning of July 2017, the first European and the second worldwide industrial pilot curing chamber was installed in a UK plant. Solidia cement produced in LafargeHolcim plant of Pecs (Hungary) was sent there to start the equipment commissioning in August.

The curing chamber installed is integrated in the precast production process to limit the OPC precast elements production disturbances. The curing chamber used in this case consists in a dedicated container equipped and secured to provide safely the CO2 required for Solidia ConcreteTM hardening. Safety information and trainings were performed for all the users and risk analyses and evaluations were anticipated to prevent any potential neighborhood disturbance.

To feed the curing chamber with pavers boards, a dedicated and sophisticated loading process was defined and put in place (right).

In the initial trial period at the end of August, some technical issues were encountered during the equipment commissioning which meant the first run of blocks, despite showing some promising characteristics, had not undergone a homogeneous and full carbonation. The UK precaster, Solidia Technologies, LafargeHolcim and Air Liquide teams have all been fully engaged in this first step and the next trial runs in mid-September look set to overcome these difficulties.

A product commissioning phase will follow the equipment commissioning to provide first relevant results on the pavers produced. At the end of the year, the UK precaster will be able to assess the added values of the Solidia Technology and anticipate the next development steps.

All the partners acknowledge the European Union for the Solid LIFE funding which supports and will continue to support the first European industrial Solidia Technologies® pilot installation and assessment.

Solidia Curing Chamber containing pavers

Pavers loading system

Solidia technology principles

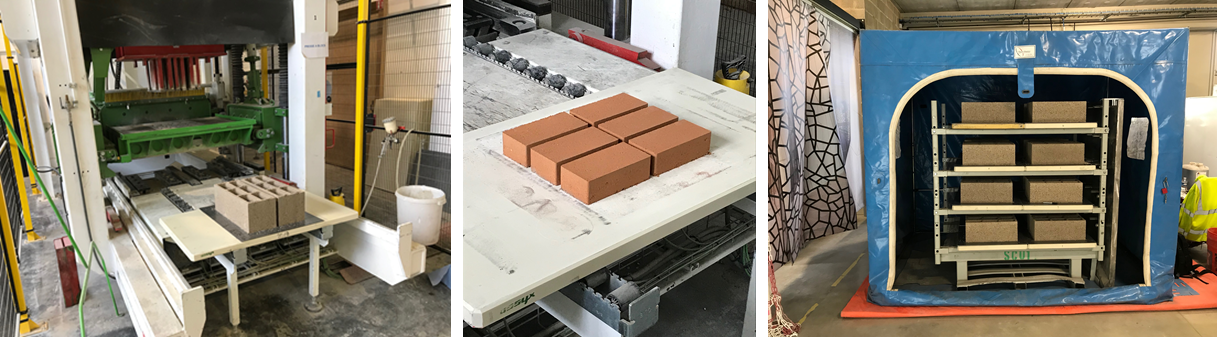

Pilot trials done at CERIB and presented during The CERIB’s Expertise day (4th of July 2019)

Three weeks of precast trials were done at CERIB premises with their equipment in order to present the main results and outcome during the CERIB’s expertise day on the 4th of July 2019.

Blocks and pavers were produced. Solidia cement was provided by LafargeHolcim to CERIB and after concrete mix design adaptations, pavers (around 4MPa, split measurement) and blocks (4MPa compressive stength) reached the strengths norms requirements. Additional characterization tests were done on aesthetics (very low efflorescence with Solidia), water absorption (2.7 on pavers), dimensional variation (swelling/ shrinkage for blocks : 0.05mm/m) and provided very good results in comparison to OPC. Freeze/Thaw tests are still on-going on pavers to get a full view of the characteristics of the concrete elements produced.

The carbonation equipment and the main results were presented during a common conference (CERIB, Suzanne Le Thierry ; LafargeHolcim France, Mouloud Behloul and Solidia, Isabelle Sgro-Rojas) on the 4th of July 2019. Solid Life project had also a booth to answer all visitors questions during the whole day. A great day, with promising discussions for future tests at precasters’ plants.